How do Self-Recharging systems work?

The main obstacle limiting further adoption of Fuel Cells however is still the means of fuel supply. Transporting hydrogen can be expensive, especially where fuel supply chains are not set up. So, faced with the following considerations, what would you do?

To decrease this obstacle, the fuel cell industry is now focusing its efforts in three areas:

To decrease this obstacle, the fuel cell industry is now focusing its efforts in three areas:

The ability to produce hydrogen on site thus taking advantage of the higher efficiencies, autonomy and reliability offered by Fuel Cells and while at the same removing fuel distribution costs completely, is the ‘holy grail’ for fuel cell adoption by many users. This is particularly relevant for countries experiencing growth in remote areas, which are serviced by unreliable grid conditions or poor infrastructure in general.

To address this need, we have developed a Self-Recharging Fuel Cell power system (SRFC). When used in conjunction with renewables, this is also referred to as the “Hydrogen Battery”.

The heart of the system is an electrolyser technology based on an Alkaline Solid Polymeric Membrane, that makes hydrogen production possible at a lower cost and more efficient energy levels, which was not possible before.

The SRFC integrates a Fuel Cell with an advanced hydrogen generator, which re-generates the hydrogen reserve on site, by using only electricity from the grid (or from renewable sources) and water. In this way, the need to replace empty cylinders with full ones is eliminated.

The SRFC integrates a Fuel Cell with an advanced hydrogen generator, which re-generates the hydrogen reserve on site, by using only electricity from the grid (or from renewable sources) and water. In this way, the need to replace empty cylinders with full ones is eliminated.

The principal behind an Electrolyser-based fuel cell is the use of excess energy from another power source, such as an unreliable grid or a renewable source, to Electrolise water to produce hydrogen, which is then stored locally until it is required.

There are basically three working modes:

Hydrogen production from water electrolysis has been available since 1800 but it has historically been energy inefficient, expensive and typically involved using an Alkaline or PEM Electrolyser approach. These systems also provided a challenge, as they require a large amount of power to start the hydrogen process and require complex balance of plant to clean or dry the hydrogen. In addition, the hydrogen pressure output from these technologies is generally at a low pressure, which requires some form of mechanical compression to store useful quantities, which is an additional energy requirement and potential liability in terms of failure.

SRFC’s AEM water electrolyser stack technology solves both cost and energy efficiency issues typically seen with existing electrolyser systems. The use of an Alkaline Solid Polymeric Membrane eliminates the need to use expensive and rare noble metals on the electrodes and enables the safe production of directly compressed hydrogen without recourse to post compressors or sophisticated pressure balancing systems, which add to the cost. The system is intrinsically simple, also saving the power required for the ancillary devices and for the compressor typically required for Alkaline or PEM based systems.

SRFC’s AEM water electrolyser stack technology solves both cost and energy efficiency issues typically seen with existing electrolyser systems. The use of an Alkaline Solid Polymeric Membrane eliminates the need to use expensive and rare noble metals on the electrodes and enables the safe production of directly compressed hydrogen without recourse to post compressors or sophisticated pressure balancing systems, which add to the cost. The system is intrinsically simple, also saving the power required for the ancillary devices and for the compressor typically required for Alkaline or PEM based systems.

The SRFC’s AES stack technology combines the benefits of a liquid alkaline Electroliser with those of a PEM membrane Electroliser. As in the alkaline system there is no need to use noble and rare metals at the electrodes, reducing costs and making the technology feasible on a giga-watt scale for global commercialization. But as in the PEM system, the hydrogen can safely be produced compressed beyond 30 bars with no need of caustic electrolyte, powered directly by intermittent renewable energy.

The SRFC’s alkaline solid polymeric membrane creates a physical barrier between hydrogen and oxygen such that they can never mix in an explosive ratio, unlike alkaline Electroliser’s where gases will blend across the porous separator when current fluctuates, making them unsuitable for powering directly from intermittent renewable energy.

While existing electrolyser technology is generally limited to 15 Bar hydrogen pressure, the SRFC AES stack can support hydrogen production and rates of over 30 Bar and can adjust production rates, in real time, to match the variable and constantly changing power output typically supplied by renewables.

The AES stack can be directly connected to an off-grid variable power source, such as solar panels or a wind generator, to produce a truly clean hydrogen fuel, hence the term “Powered by Nature”. The SRFC’s alkaline membrane, unlike the PEM membrane repels most metal ions and can be supplied with filtered rainwater for completely service-free off-grid autonomous operation.

A significant consideration with an SFRC is,

1). How much storage can I realistically have in terms of pressurized vessels on site?

2). How much time do I have to replace the hydrogen used, once my energy source returns?

Unlike a Reformer based system (like an MFC), we realistically need to think in terms of operating the SRFC like a long duration battery, hence the term “Hydrogen Battery”.

A comparison between running a SRFC against any ‘fuel’ based system is simple. Once I have time to replace the hydrogen used, I will always be operating and will never run out of fuel. Autonomy, for any single outage is dependent on the size of the storage vessel being used.

A comparison between running a SRFC against any ‘fuel’ based system is simple. Once I have time to replace the hydrogen used, I will always be operating and will never run out of fuel. Autonomy, for any single outage is dependent on the size of the storage vessel being used.

For storage vessel’s, the norm is to use a 1m3 cylinder, which at the Electroliser output of 30Bar, pressure supports 30,000L of H2. This 1m3 cylinder has the same ‘footprint’ as the system cabinet however is narrower and not so high so can be incorporated into the system cabinet. There is no limit however to the number of cylinders you can use. The SRFC Electroliser is available with two production rates which are 500L per hour or 1000L per hour. At full production, it would take 30 hours to completely fill a 1m3 vessel.

For storage vessel’s, the norm is to use a 1m3 cylinder, which at the Electroliser output of 30Bar, pressure supports 30,000L of H2. This 1m3 cylinder has the same ‘footprint’ as the system cabinet however is narrower and not so high so can be incorporated into the system cabinet. There is no limit however to the number of cylinders you can use. The SRFC Electroliser is available with two production rates which are 500L per hour or 1000L per hour. At full production, it would take 30 hours to completely fill a 1m3 vessel.

As an option, a compressor can be used to increase the output from the Electroliser from 30Bar to 200Bar thus expanding the storage options further such as using the more commonly available 50L cylinders.

As an option, a compressor can be used to increase the output from the Electroliser from 30Bar to 200Bar thus expanding the storage options further such as using the more commonly available 50L cylinders.

As an example, a ‘magazine’ of 6 high pressure vessels’ at 200Bar would hold 60,000 Liters of Hydrogen and take up the same footprint. A combination of Low Pressure Vessels’ and High Pressure vessels’ can also be used to cover long duration outages which are seasonal.

The time required to refill the hydrogen used depends on the amount of hydrogen used during the outage. As with systems running on H2Go the consumption of hydrogen is based on a fixed amount of hydrogen per kW hour. The consumption of the fuel cell stack is 670L of Hydrogen per kW hour and like the MFC systems this rate is linear, regardless of the load. The time to replace the H2 used is then dependent on the production rate of the Electroliser.

Example, 1m3 Cylinder and a 2kW load and a 4kW load

| Low Pressure Storage | Cylinder | Pressure | Total | Autonomy |

| Size (L) | Bar | H2 (L) | Kw/Hours | |

| 1000 | 30 | 30,000 | 44.77 |

With a 2kW load my Total Available Autonomy is 22.34 Hours.

4-hour Outage

8-hour Outage

With a 4kW load, Total Available Autonomy is 10.7 hours

4-hour Outage

8-hour Outage

Renewable energy such as Solar PV or Wind is extremely ‘variable’ as a primary source of power, with typically, no power when you need it, or too much at the wrong time. Batteries are traditionally used as an energy store to ‘time shift ‘power for use later however, while they may be efficient at storing energy, the real issue is the cost and efficiency of discharging these, while at the same time providing the autonomy needed.

We need to use technology that exploits Hydrogen fuel’s potential as a ‘energy store’, in combination with renewables and the SRFC does just that by;

Solar panels generate power during sunlight hours however much of the time most of this energy is not utilized as there has not been a viable way to do capture and store this. Solar/Battery configurations are designed to make best use of sunlight during the worst days hence large panels and batteries are needed as the site load requirements increase.

Solar panels generate power during sunlight hours however much of the time most of this energy is not utilized as there has not been a viable way to do capture and store this. Solar/Battery configurations are designed to make best use of sunlight during the worst days hence large panels and batteries are needed as the site load requirements increase.

Existing Batteries are typically recharged in a 3.5-hour window during the peak solar output in a sunlight day, hence the balance of the solar energy is in effect wasted.

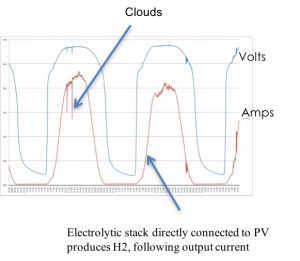

The design of the SRFC’s AEM Electroliser enables it load follow the available input power coming from renewables. The production of H2 can start in low volumes, once the balance of plant has enough energy to operate and H2 production can mirror the input power available, once the balance of plant operates (200W).

This means H2 production can start early in the morning at 100L of H2 per hour and ramp up to 1000L per hour during solar peak production. Batteries are not efficient at completely harvesting all the available solar energy generated by a PV system as most batteries have a charging characteristic that requires a specific input current to properly charge. In addition, due to the cost per kW hour of storage, batteries not viable for any long autonomy purposes.

The SRFC on the other hand, can fully capture or ‘harvest’ most of the PV generated and can keep doing so was long as there are low cost storage vessels available.

The SRFC on the other hand, can fully capture or ‘harvest’ most of the PV generated and can keep doing so was long as there are low cost storage vessels available.

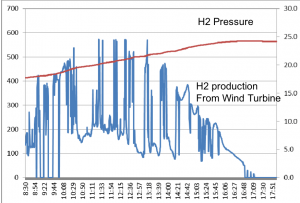

This feature of H2 production following the power available to the Electroliser cannot be underrated and this has proven itself in under the most extreme variable conditions such as providing energy storage for wind turbines in the Faro Islands, where the input power varies by the minute and in Solar PV sites which are frequently effected by cloud cover.

To produce 1m2 of H2 in one hour the AEM Electroliser consumes 0.89 Liters of water, which is equivalent to 1.49kW of power.

One option is to collect and store rain water or simply use a large 200L water tank that would require filling only once a year. Another option is to make your own water by using an on-site reverse humidifier. This is possible in many countries where the humidity level is high (40%) and requires only a modest amount of energy to do so (100W). The production capability can be up to 250L of water produced per day and they system is designed to operate only where there is excess power available (i.e. batteries charged, load covered and H2 tanks already full).

The SRFC’s unique ability to “self-recharge” either via the electrical grid or when used in conjunction with renewables make this a unique solution in you have the performance advantages of a fuel cell, with no fuel logistics such as H2Go or H2 cylinders. For critical telecom infrastructure network backup power applications, this technology offers several advantages:

Quite Simply, SRFC is ….. Powered by Nature !